RAC Pylons speed inbound weighing at world's largest linerboard plant

November-22-11

Counce Tennessee; Packaging Corporation of America has taken delivery of the remaining RAC Pylons from their first order to The Kiosk Factory.

The Counce facility has two linerboard machines and is PCA's highest volume mill, producing about 998M tons annually. The #1 paper machine primarily produces many high-performance, wet-strength, and other specialty grades. The #2 paper machine was completely rebuilt in 1996 and is a world-class, state-of-the-art, lightweight linerboard producer.

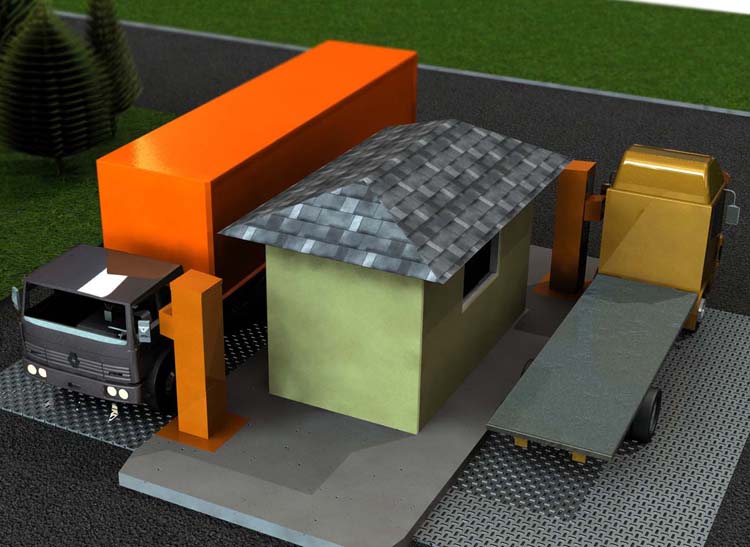

Primary to the needs of this high volume production facility was the ability to streamline the raw materials weighing process. One process improvement that was identified was the requirement to keep drivers within their trucks to reduce the time needed to weigh the full inbound trucks and then the empty outbound. The RAC Pylon fits the requirement perfectly.

Drivers identify themselves with barcode encoded cards that are scanned by the adjustable instrument platform, drivers communicate with the weigh in station via two way voice communication and scale tickets are provided to the drivers without ever having to move from the vehicle.

The time savings involved in keeping drivers within their trucks for this high volume environment meant that additional lanes of scales (and staff) were not needed to improve effeciency. The RAC Pylon is ideally suited for this role as well as access control, parking, fee collection, quick service (including payment), enrollment or any driver interaction with a remote 2nd person.

Call The Kiosk Factory for more information on how the RAC Pylon can cut your load processing time and improve commodity throughput.